Custom Plastic Profile Extrusion Die Design

With over 65 years of experience in custom profile extrusion, our team of plastic profile tooling and design engineers are qualified to help you design a profile that not only meets your needs but allows us to provide you with the best cost solution. Northland Plastics has developed over 4000 profiles since 1953 and we're eager to assist you in designing a custom plastic profile extrusion for your application. Our focus is on state-of-the-art design and continuous improvement, which aligns with our extensive history of producing quality parts at competitive prices. There are many things to consider during the design process, and our engineers ask the right questions to ensure the finished profile meets your performance requirements. We've helped countless customers improve or re-design new and existing parts to increase quality and repeatability as well as reduce costs.

Plastic Material Selection & Engineering Support

In addition to helping design your part we can assist you in selecting the appropriate material. There are many thermoplastic compounds available, and choosing the best one for an application can be difficult. Our experienced staff and qualified supply base have the experience and resources necessary to assist you in selecting the best material for the job. We pride ourselves in finding creative cost saving solutions, and alternate materials are one way we've provided cost savings while still maintaining all design and engineering characteristics required for the extruded part.

Engineering Successful Plastic Alternatives to Wood, Metal & Rubber

Many of our customers work with us to convert existing products in metal, wood and rubber to plastic extruded profiles. Our engineering and design team works with each client to not only realize significant cost savings by switching to plastic extrusions, but to help design a replacement part meeting all of the same physical specifications and requirements.

How Engineering Drives Cost-Effective Extrusion Design

Successful plastic profile extrusion begins with thoughtful engineering. Northland Plastics combines decades of experience with modern design tools to ensure each profile meets performance requirements while minimizing material waste and tooling complexity. Our engineers collaborate with customers to refine part geometry, wall thickness, and tolerances, resulting in better manufacturability and lower production costs.

Material Selection for Performance and Efficiency

Choosing the right thermoplastic compound is important to extrusion success. Northland Plastics helps customers evaluate materials based on environmental exposure, mechanical properties, and cost targets. Whether you're replacing metal, wood, or rubber components, our team ensures the selected plastic meets all functional and regulatory requirements.

In-House Tooling for Faster Turnaround

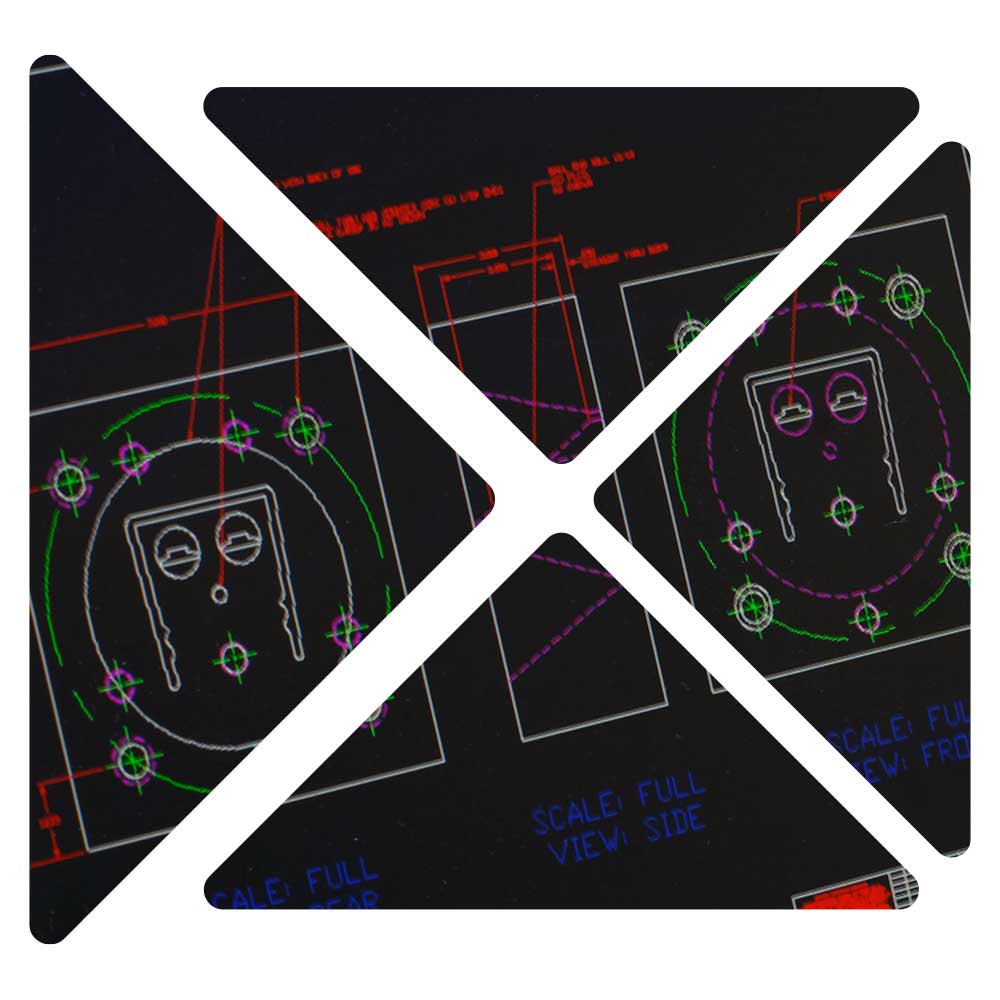

Northland’s vertically integrated facility allows us to design and build extrusion dies, vacuum calibration tools, and fabrication fixtures entirely in-house. This control over the tooling process shortens lead times, improves precision, and ensures repeatability across production runs. Our wire EDM and CNC machining centers deliver the accuracy needed for complex profiles and tight tolerances.

Frequently Asked Questions (FAQ)

What Is Plastic Profile Extrusion Die Design?

It’s the process of engineering a custom die that shapes molten plastic into a specific profile. The die determines the geometry, dimensions, and surface finish of the final extruded part.

Can You Help Me Replace a Metal or Rubber Part with Plastic?

Yes. We specialize in converting components from metal, wood, or rubber to plastic extrusions. Our engineers ensure the new part meets all original specifications while offering cost and performance advantages.

How Long Does It Take to Create a Custom Extrusion Tool?

With our in-house tooling capabilities, we can design and produce a custom extrusion die in as little as two weeks, depending on complexity.

What Materials Can Be Used for Custom Extrusions?

We work with a wide range of thermoplastics including ABS, PVC, polyethylene, polypropylene, TPE, TPU, and more. We also help source alternative compounds based on your application needs.

Do You Handle Both Design and Manufacturing?

Absolutely. We offer end-to-end support, from initial design and material selection to tooling, extrusion, and secondary operations, all under one roof.

Plastic Profile Tooling Made In-House

All extrusion, vacuum calibration and fabrication tooling is designed by our engineers at our vertically integrated facility. Tooling is then built in-house using our wire EDM CNC machining centers. We have a full machine shop which yields the precision streamline tools needed to deliver high quality parts and repeatable processes. Designing and producing all tooling internally shortens lead times and eliminates reliance on outside manufacturing. We believe the greatest results start with proper tooling. Having complete control over the plastic profile tooling and extrusion die process allows us to be both nimble and robust in our design and execution of plastic fabrication.

Contact us for expert engineering support for any aspect of your plastic profile extrusion. Located in Sheboygan, WI, Northland Plastics serves customers throughout Wisconsin and nationwide.